Building Trust in the Digital Supply Chain: The Role of ISO 27001 in Manufacturing

Information is the most valuable commodity in modern manufacturing. The supply chain has shifted far beyond the physical movement of materials, now spanning vast digital networks that connect suppliers, design partners, and production sites through continuous data exchange. As technologies reshape how information flows, data security has become a key foundation of reliability and trust.

This is where ISO 27001, the international standard for information security management, plays a vital role. It defines how organizations protect the confidentiality, integrity, and availability of information — from internal operations to customer data — across the entire business ecosystem.

Understanding ISO 27001: More Than a Certificate

ISO 27001 is a globally recognized framework for establishing, implementing, and maintaining an Information Security Management System (ISMS). It provides a structured approach to managing risks, protecting sensitive data, and ensuring business continuity.

At its core, ISO 27001 ensures three essential principles:

- Confidentiality – information is accessible only to authorized personnel.

- Integrity – data remains accurate and unaltered.

- Availability – systems and information are accessible when needed.

In electronics manufacturing, these principles are essential. Every stage — from design to production — involves data that must remain protected: product specifications, CAD drawings, Bills of Materials (BOMs), supplier details, and production analytics. ISO 27001 provides the comprehensive framework and discipline necessary to safeguard this information while maintaining efficiency and transparency.

Why Information Security Matters in Manufacturing

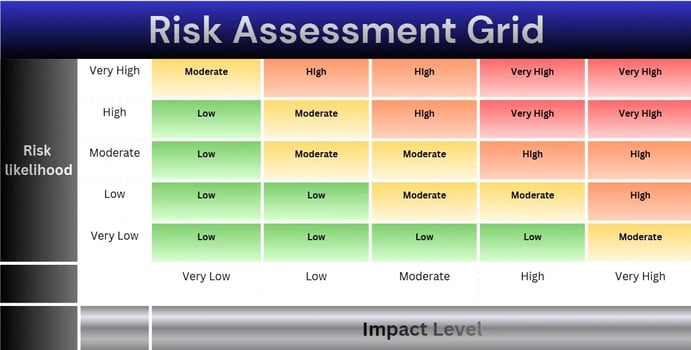

Manufacturing today operates as a connected ecosystem. Real-time data flows between design platforms, ERP systems, and production lines. This interconnectivity enables speed and flexibility — but it also introduces new risks such as data breaches, IP theft, or operational disruptions.

For an Electronics Manufacturing Services (EMS) provider, these risks carry significant implications. A single vulnerability could affect product integrity, delay deliveries, or expose confidential design information. For this reason, a resilient, secure environment is not a compliance measure — it is the foundation for protecting customer trust and ensuring operational continuity.

By integrating ISO 27001 principles, manufacturers can proactively identify potential threats, implement preventive measures, and strengthen the integrity of their digital supply chain.

Integrating Security into the Manufacturing DNA

At SVI, information security is not treated as a standalone initiative — it is part of how we operate every day. To truly embed security into the core of our operations, we go beyond certification. For an advanced electronics manufacturer, this means deploying specific, high-impact controls that protect our most critical assets: our customers’ Intellectual Property (IP) and the continuity of our production lines.

Protecting Your Intellectual Property (IP) and Design Data

For example, SVI enforces strict, role-based access controls to all critical design files, including CAD data and Bills of Materials (BOMs). Access is strictly limited to personnel specifically authorized for each project and is immediately revoked upon role or project completion. We also employ Data Loss Prevention (DLP) technologies on design servers to monitor and prevent unauthorized data transfers. In addition, Multi-Factor Authentication (MFA) is required for all remote access to our Product Lifecycle Management (PLM) systems, providing multiple layers of defense to safeguard customer innovations.

Supporting Production Integrity and Operational Resilience

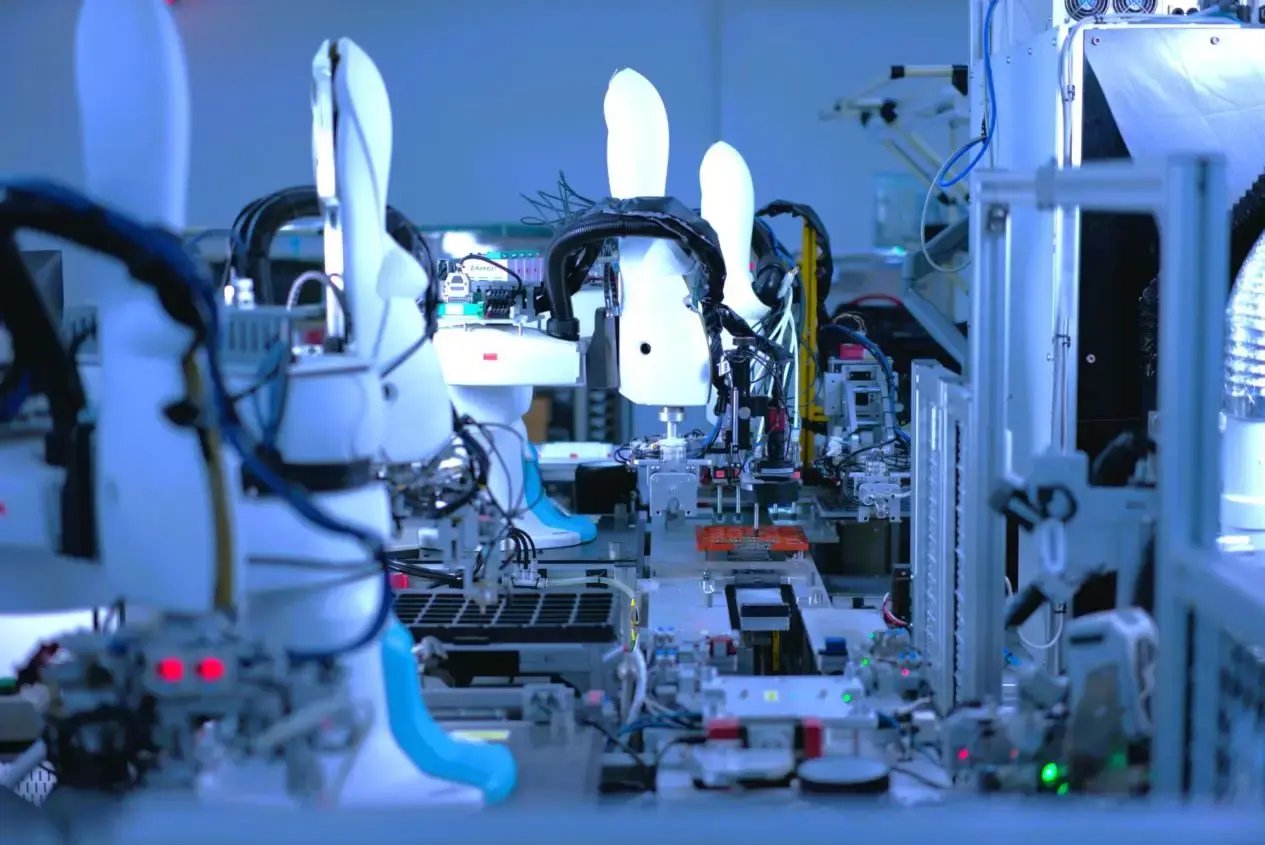

A second example is how SVI protects its manufacturing systems through rigorous network segmentation and change management for all Operational Technology (OT) environments. The factory floor network — which controls machines, robots, and automation — is strictly isolated from the corporate IT network. Any changes to the firmware or software that control production equipment must follow a formal Change Management Process, including risk assessment, verification, and secure backups. This approach prevents unauthorized modifications, enhances traceability, and reduces the risk of external cyber threats impacting production.

A second example is how SVI protects its manufacturing systems through rigorous network segmentation and change management for all Operational Technology (OT) environments. The factory floor network — which controls machines, robots, and automation — is strictly isolated from the corporate IT network. Any changes to the firmware or software that control production equipment must follow a formal Change Management Process, including risk assessment, verification, and secure backups. This approach prevents unauthorized modifications, enhances traceability, and reduces the risk of external cyber threats impacting production.

Ensuring Business Continuity and Disaster Recovery

SVI’s information security approach also extends to business continuity planning. Critical servers, including those that host ERP, MES, and PLM systems, are backed by redundant infrastructure and mirrored backups across secure locations. Routine disaster recovery drills are conducted to validate recovery times and ensure minimal disruption in case of system failure or cyber incidents.

Monitoring and Continuous Improvement

ISO 27001 requires a culture of continuous improvement — one that SVI fully embraces. Security audits, vulnerability assessments, and employee awareness programs are carried out on a regular schedule. Lessons learned from audits are directly applied to strengthen controls and enhance security awareness across all teams.

These measures illustrate how ISO 27001 principles are not just documented policies at SVI — they are actively applied, regularly tested, and continually improved within real factory operations.

Trust Through Transparency

At SVI, we believe that information security fosters trust — and trust is the foundation of lasting partnerships. Our ISO 27001 certification demonstrates SVI’s dedication to safeguarding customer information, supporting business resilience, and upholding high standards of operational excellence

As the manufacturing ecosystem becomes increasingly digital, maintaining this discipline across every process helps SVI and its partners work with confidence — knowing that every piece of information, from design concept to final assembly, is protected with the same level of care as the products we build.

Conclusion

ISO 27001 is more than a security standard — it is a mindset of continuous protection and improvement. At SVI, this mindset is deeply integrated into our manufacturing operations, ensuring that customers’ data and production systems are secure, resilient, and trusted.

As manufacturing evolves with AI-enabled analytics, 5G-connected systems, and data center integration, maintaining ISO 27001 discipline ensures that innovation continues on a secure foundation. By embedding this security mindset into every process, SVI strengthens the reliability of the global digital supply chain — one trusted connection at a time.

As manufacturing evolves with AI-enabled analytics, 5G-connected systems, and data center integration, maintaining ISO 27001 discipline ensures that innovation continues on a secure foundation. By embedding this security mindset into every process, SVI strengthens the reliability of the global digital supply chain — one trusted connection at a time.

Ready to Strengthen Your Supply Chain Security?

Contact SVI to discuss how our ISO 27001-certified manufacturing infrastructure can support your next project.

Supanee Nookaew

Supanee Nookaew