Preparing BMS Designs for Reliable Manufacturing | Tohoku Solutions’ Engineering Approach

Battery Management Systems (BMS) combine high-accuracy sensing, protection logic, and thermally sensitive components. Even when customers provide a complete BMS design, manufacturability challenges often emerge when transitioning from engineering samples to mass production. Variations in layout, thermal distribution, component tolerances, or assembly conditions can influence stability, measurement accuracy, and yield performance.

Tohoku Solutions supports customers by evaluating their designs from a manufacturing perspective and ensuring a stable, controlled transition into production. As a one-stop EMS provider within the SVI Group, Tohoku performs DFX reviews, prototyping, NPI, and mass production at a single facility. This integrated structure shortens engineering cycles, reduces variation, and strengthens process consistency throughout the production lifecycle.

1. One-Stop EMS for BMS and Power Electronics

Tohoku supports the full manufacturing lifecycle of BMS and power electronics, allowing engineering evaluation, prototyping, NPI, and mass production to be carried out within a single facility. This integrated setup reduces variation between phases and avoids the typical handover gaps seen when engineering and production are split across different organizations.

With all activities executed internally, Tohoku can maintain consistent process control and apply early findings from prototyping directly into NPI and mass production.

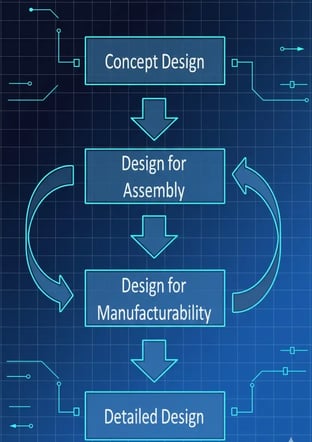

2. Why DFX Matters for BMS Manufacturing

The shift from engineering samples to mass production often exposes manufacturability issues that were not apparent during early testing. BMS assemblies, in particular, are sensitive to layout practices, thermal behavior, copper design, component placement, and insulation requirements.

These factors directly affect yield stability, long-term reliability, and electrical performance in high-volume production. For this reason, a comprehensive DFX review is essential before entering NPI, enabling potential issues to be addressed at a stage where corrective actions are less disruptive.

3. Tohoku’s DFX Review Methodology

3.1 Schematic Review

Tohoku reviews schematics with attention to BMS-specific requirements such as:

- Voltage measurement accuracy and filtering architectures

- Current-sensing topology and Kelvin routing considerations

- MOSFET drive circuitry, switching characteristics, and margin analysis

- Protection thresholds, redundancy, and fault-handling logic

- Temperature detection paths and distribution

- Separation between HV and LV domains

The goal is to ensure the design supports stable, safe operation under actual production conditions.

3.2 Layout Review

PCB layout plays a critical role in thermal behavior, electrical accuracy, and mechanical robustness.

Key areas evaluated include:

- Creepage and clearance distances for HV insulation

- Copper width and thickness for high-current paths

- Shunt resistor placement and proper Kelvin routing

- Isolation between analog sensing and switching regions

- Thermal spreading around power components and balancing resistors

- Connector alignment and mechanical stress points

- Pad designs that may cause reflow defects

Addressing these factors early helps prevent drift, noise coupling, thermal imbalance, and reliability issues during MP.

3.3 Manufacturability Review

Manufacturability checks focus on how well the design fits within automated production processes. Tohoku evaluates:

- Reflow profile compatibility

- Component spacing, orientation, and SMT placement tolerances

- Avoidance of manual soldering and secondary operations

- BOM lifecycle, sourcing risk, and long-lead components

- Panelization strategy and board rigidity

This review minimizes the need for late-stage corrections during NPI or MP.

4. Prototyping and NPI Execution

Prototypes are assembled using the same SMT equipment and process controls applied in mass production. This approach allows early verification of:

- Solder joint behavior across critical components

- Thermal distribution around high-power sections

- Electrical measurement stability

- Mechanical fit and interface alignment

Traceability in Prototyping and NPI

Tohoku implements unit-level traceability from the prototype stage, including:

- Component lot records

- SMT placement and reflow machine parameters

- SPI/AOI inspection data

- Measurement and evaluation results collected during NPI

This data allows engineers to correlate manufacturing variations with electrical outcomes and refine the design or process before mass production.

5. Mass Production at Tohoku

Tohoku performs mass production using the same engineering framework established during DFX and NPI. The production flow includes:

- Automated SMT and selective soldering

- SPI and AOI inspections

- Electrical checks and measurement calibration

- High-voltage isolation testing

- Mechanical inspection and final verification

Unit-Level Traceability in Mass Production

Traceability is fully maintained across MP, tracking:

- Component lots

- All critical SMT and assembly machine data

- SPI/AOI inspection outputs

- Calibration and electrical verification results

- Serial-number mapping through every stage

This supports long-term reliability analysis, faster problem resolution, and stable yield improvement.

6. Benefits to Customers

A typical result of Tohoku’s structured DFX review and integrated manufacturing flow is improved predictability during industrialization. By addressing manufacturability issues early and maintaining consistent engineering oversight through prototyping, NPI, and mass production, customers experience fewer disruptions during ramp-up.

As a result, customers working with Tohoku generally see:

- Earlier identification of manufacturability concerns

- Fewer design revisions during industrialization

- Stable yield at the start of mass production

- Shorter overall development and ramp-up time

- Predictable performance supported by traceability data

- Consistent engineering support across all phases of the project

This reduces the overall risk profile of BMS manufacturing and contributes to better long-term reliability in the field.

Conclusion

BMS manufacturing requires close alignment between design intent and production behavior. Tohoku Solutions provides a structured, engineering-driven approach that prepares customer designs for stable mass production. Through in-house DFX review, prototyping, NPI, mass production, and complete traceability, Tohoku supports a reliable and repeatable manufacturing pathway for BMS and power electronics based on customer-owned designs.

Supanee Nookaew

Supanee Nookaew

.png?width=64&height=64&name=artificial-intelligence%20(3).png)