End-to-End BMS Manufacturing for EVs | Tohoku Solutions

As electric vehicles (EVs) gain momentum worldwide, the systems behind them are evolving rapidly. One of the most critical components in a Battery Electric Vehicle (BEV) is the Battery Management System (BMS)—a system responsible for monitoring and controlling the battery's voltage, current, and health. Unlike traditional gasoline-powered cars, EVs require BMS and CMS (Cell Management System) to ensure safe operation and extend battery life.

Tohoku Solutions, a subsidiary of SVI, brings over 30 years of automotive electronics experience and 2 years of dedicated BMS manufacturing. We currently produce BMS for a Chinese EV brand, with production for a European automaker starting in August and discussions underway with U.S. customers. Here’s how Tohoku turns BMS concepts into complete, road-ready solutions.

1. Early Engagement: From Concept to Design for Manufacturing (DFM)

Our journey begins with close collaboration during the early design stage. By partnering with customers at the concept level, we help ensure:

- The product is designed for manufacturability, testability, and reliability.

- Critical safety and thermal considerations are addressed early.

- Component availability and cost targets are optimized.

Our design for manufacturing (DFM) expertise, especially in automotive-grade electronics, reduces risk and accelerates time-to-market.

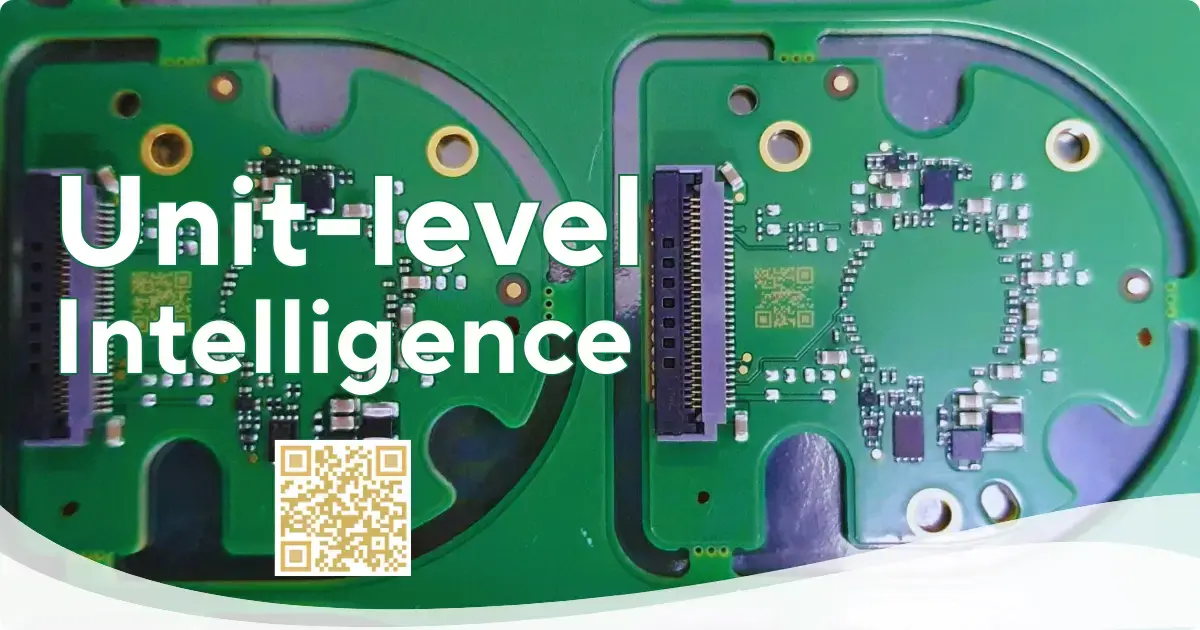

2. Precision PCBA Assembly: Automotive-Grade Standards

In addition to SMT and PCBA processes, we support BMS with custom die molds, metal and plastic component manufacturing, and in-house wire harness production. This enables tight control over part quality and compatibility from the ground up.

|

|

|

Tohoku applies automotive manufacturing principles to every BMS project:

- IATF 16949-certified processes for quality assurance.

- Full traceability from material to module.

- Controlled environments to ensure consistent soldering quality, especially for power electronics and mixed-signal circuits.

We handle complex, multilayer PCBs that incorporate microcontrollers, cell monitoring ICs, current sensors, and communication interfaces—all with high-density layouts.

3. Intelligent Testing: Beyond Visual Inspection

BMS requires more than visual and AOI checks. Tohoku invests in custom functional testers, including:

- High-voltage isolation and leakage detection.

- Balancing function validation.

- CAN/LIN communication checks.

- Embedded firmware flashing and verification.

Our test systems simulate real-world operating conditions to validate each board’s intelligence and safety logic.

4. System Integration & Box Build

Tohoku doesn’t just assemble—we design and produce plastic enclosures, metal components, and customized connectors. By managing the entire value chain, we ensure all parts are built to spec, tested, and seamlessly integrated.

Beyond the board, we provide complete system integration:

- Plastic or metal housing assembly

- Connector mounting, potting, and thermal interface materials

- Embedded component sealing to protect against moisture and vibration

This level of vertical integration reduces handoffs and improves quality control—especially important in automotive applications where failure is not an option.

5. Final Validation & Logistics

Before shipping, every BMS unit undergoes burn-in, end-of-line testing, and compliance documentation based on customer specifications.

As part of the SVI global network, we also offer:

- Logistics support for just-in-time (JIT) delivery.

- Regional manufacturing flexibility.

- Strategic cost competitiveness without compromising Japanese quality standards.

Why Tohoku for BMS?

✅ Proven track record in automotive EMS since 1990s

✅ In-house testing and box-build capabilities

✅ Full compliance with functional safety and traceability standards

✅ Seamless integration into global supply chains through SVI

✅ Currently producing BMS for EV brands in China and expanding to Europe and the U.S.

✅ Vertically integrated: from mold design and injection to wire harness and final test

✅ Trusted by global OEMs for quality, reliability, and scalability in BMS production

From concept to car, Tohoku Solutions delivers peace of mind through complete BMS manufacturing—from board to box, plastic to PCBA, and prototype to production. Backed by decades of experience and trusted by today’s EV innovators, we’re proud to support the future of mobility.

Ready to bring your BMS project to life?

Partner with a manufacturer who understands the demands of EV innovation from the inside out.

Contact us today to discuss how Tohoku Solutions can support your next-generation battery system.

Supanee Nookaew

Supanee Nookaew

.png?width=64&height=64&name=artificial-intelligence%20(3).png)