How to Build a Culture of Continuous Improvement in Electronic Contract Manufacturing

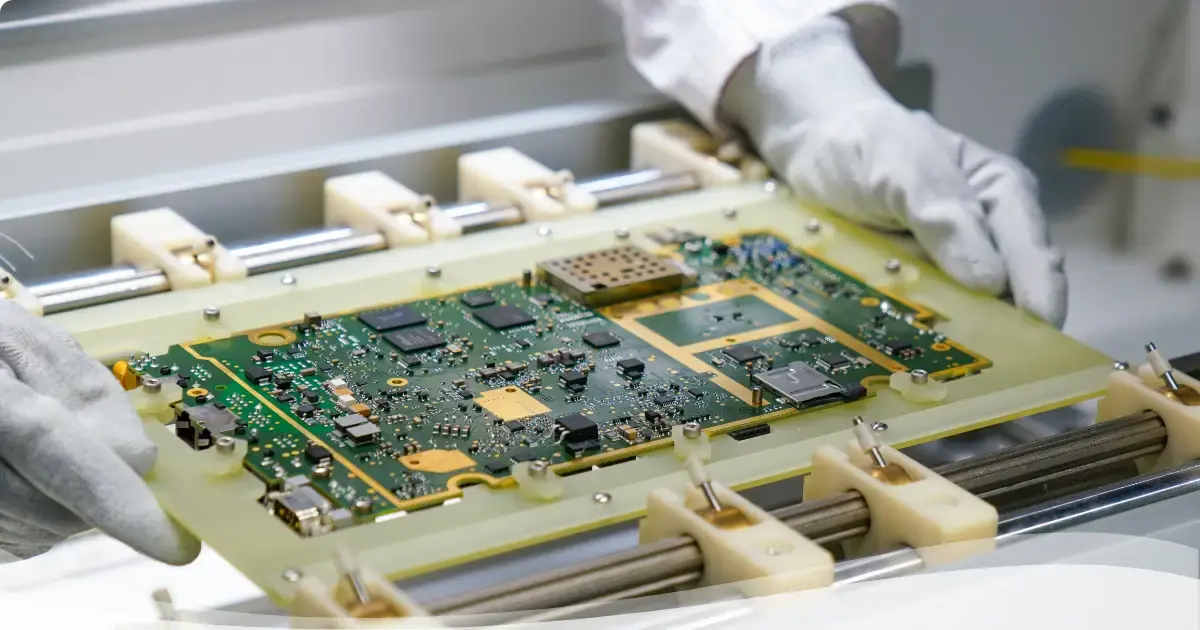

In today’s fast-paced manufacturing world, customers are looking for more than just a supplier—they need a strategic partner who can help them stay competitive. In the U.S. and globally, Electronic Contract Manufacturing (ECM) and Electronics Manufacturing Services (EMS) providers are expected to deliver not only quality and speed but also continuous optimization.

At SVI, continuous improvement (CI) is not a department—it’s a company-wide culture. From Lean Six Sigma to Kaizen and digital transformation, we’ve built a system that helps customers benefit from smarter, faster, and more sustainable manufacturing.

-

Why Continuous Improvement Matters in ECM

In the electronics industry, market demands change quickly. Launch cycles are shorter, cost pressure is increasing, and traceability and compliance are more important than ever.

That’s where CI comes in. A culture of continuous improvement ensures that your manufacturing partner isn’t just maintaining performance—they’re constantly elevating it. For OEMs, this means:

- Faster time to market

- Reduced cost of poor quality

- More flexible production

- Greater long-term value

-

The SVI Approach: Structured Improvement with Real Results

SVI’s continuous improvement journey has evolved through years of practical experience, grounded in proven methodologies and measurable outcomes. Our approach is deeply embedded across all operations and continues to grow at every level of the organization:

- Lean Six Sigma: Supported by certified Black Belt professionals, we apply Lean Six Sigma methodologies to drive data-informed improvements that enhance quality, reduce waste, and optimize performance.

- Kaizen Thinking: Small, continuous improvements on the shop floor help eliminate waste, improve production flow, and maximize resource efficiency.

- SMART Meetings: Our regular cross-functional CI reviews enable teams to quickly identify opportunities, implement solutions, and maintain momentum through clear accountability.

- Digital Tools: We leverage tools such as OEE (Overall Equipment Effectiveness), OLE (Overall Labor Efficiency), and our custom Andromeda platform to gain real-time operational visibility.

Whether it's process optimization, logistics, or energy management, every touchpoint is seen as an opportunity to improve.

-

What This Means for Our Customers

Our customers—particularly in the U.S.—work with us because they need a reliable and agile electronic contract manufacturer. CI helps us meet that need by:

- Increasing first-pass yield and quality consistency

- Reducing waste and lowering manufacturing costs

- Enhancing speed and delivery accuracy

- Driving sustainability initiatives that align with ESG goals

CI isn’t just an internal benefit—it’s a direct value to every OEM we support.

-

CI That Scales Across Global Manufacturing Sites

SVI’s continuous improvement practices are standardized across our global sites in Thailand, Cambodia, Slovakia, Austria, and the USA. That means whether your products are built in Southeast Asia or nearshore in Washington state, you can expect the same high-performance execution—backed by a culture of accountability and constant optimization.

In 2023, this approach was recognized when SVI earned 2nd place in the Kaizen Thailand Award, highlighting our ability to apply CI principles in real production settings across departments.

Conclusion

Choosing an EMS or ECM partner isn’t just about price and capacity—it’s about long-term value. At SVI, our culture of continuous improvement ensures that every customer benefits from better quality, smarter operations, and more responsive service.

If you’re looking for a forward-thinking electronic contract manufacturer who never stops improving, let’s talk.

Supanee Nookaew

Supanee Nookaew

.png?width=318&height=201&name=mm-ebook%20(1).png)